Abstract

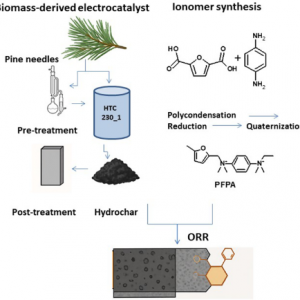

Anion Exchange Membrane Fuel Cells (AEMFCs) are promising clean energy devices. To align their developmentwith sustainability goals, this study explores the integration of biomass-derived components into AEMFC cathodes.Biochar-based electrocatalysts were synthesized via hydrothermal carbonization (HTC) of pine needles, a water-based, low-temperature process. Three processing strategies were investigated: direct HTC of raw biomass,HTC following biomass pre-treatment, and thermal post-treatment of the resulting hydrochar to promotegraphitization. In parallel, a biomass-derived anion exchange ionomer (AEI) was synthesized via polycondensationof 2,5-furandicarboxylic acid with p-phenylenediamine, followed by reduction and quaternization. The resultingfuran-based AEI was incorporated into the cathode and benchmarked against a PPO-based ionomer (PPO-LC).Electrochemical testing showed that the furan-based AEI led to lower performance, particularly fewer exchangedelectrons, though onset potentials remained comparable to the Pt/C reference. Hydrochar derived from raw pineneedles demonstrated favourable performance with minimal processing, avoiding organic solvents and loweringthe energy demand. In contrast, a high temperature post-treatment offered only marginal performance gainsat high energy cost, limiting its sustainability. This study highlights the importance of balancing performance,processing effort, and environmental impact in AEMFC electrode development.

Illustrations

Details

Published on: Journal of Materials Science: Materials in Energy 2025, 1, 7

Authors: S. Chandrasekaran, R. Narducci, E. Sgreccia, A. Haider, L. Pasquini, A. Marrocchi, E. Cerza, M. L. Di Vona and P. Knauth